- News

- Women

- Magazine

- IndustryIndustry

- InsightsInsights

- Success Stories

- PublishPublish

- ContactContact

- Media KitMedia Kit

For decades, executives viewed physical assets primarily through the lens of accounting: as depreciating items on a balance sheet. This perspective, while financially necessary, overlooks a fundamental truth. A company's machinery, facilities, and vehicle fleets are not just costs to be managed; they are the very engines of value creation. In today's competitive environment, shifting from a passive accounting view to an active strategic one is essential for sustainable growth.

The traditional approach to asset care has been largely reactive. When a critical piece of equipment fails, operations grind to a halt, and teams scramble to fix it. This break-fix model is inherently inefficient, leading to unpredictable downtime, inflated repair costs, and frustrated customers. The modern paradigm is a strategic evolution towards proactive and predictive management, where data and technology are used to anticipate needs, prevent failures, and optimize performance across an asset's entire lifecycle.

Thinking strategically about assets means recognizing their direct impact on the bottom line. Every hour of unplanned downtime is an hour of lost revenue. Every premature equipment replacement is a hit to capital expenditure that could have been deferred or avoided. A well-executed Enterprise Asset Management (EAM) strategy transforms the maintenance department from a cost center into a driver of profitability and a source of competitive advantage.

This forward-thinking approach is built on a foundation of data. By monitoring asset health, tracking performance metrics, and analyzing historical trends, organizations can move beyond a fixed maintenance schedule. They can predict potential failures before they happen, allowing for planned interventions that minimize disruption and maximize operational availability.

Adopting a modern EAM strategy delivers tangible benefits that resonate directly in the boardroom. These advantages go far beyond simply keeping the lights on; they fortify the entire enterprise.

The most immediate impact of strategic asset management is a significant reduction in unplanned downtime. When equipment runs reliably, production schedules are met, service delivery is consistent, and the entire value chain functions more smoothly. This stability allows for better resource planning and drives higher overall productivity.

Significant capital is invested in major physical assets. Proactive maintenance and strategic planning ensure the organization extracts the maximum possible value from these investments. By extending the useful life of machinery and infrastructure, companies can delay major capital expenditures and improve their return on assets.

In many industries, strict regulatory and safety standards govern the operation of physical assets. A systematic approach to asset management provides a clear audit trail, ensures compliance with industry regulations, and reduces the risk of safety incidents, protecting both employees and the company's reputation.

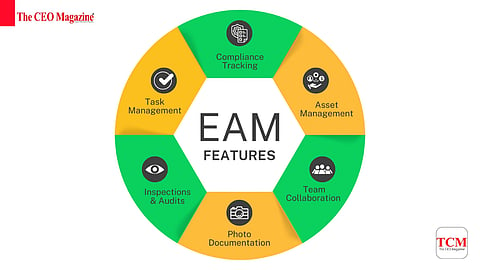

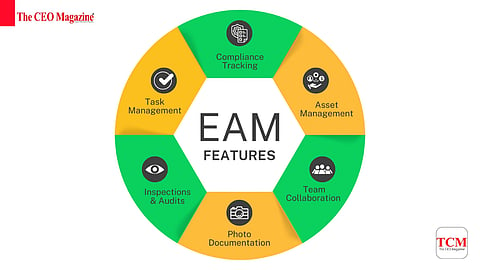

Executing a sophisticated EAM strategy is impossible without the right technological foundation. Modern platforms provide a centralized, 360-degree view of an organization's entire asset portfolio, from acquisition to disposal. This holistic visibility is critical for making informed, data-driven decisions. The right enterprise asset management software integrates data from across the organization, providing leaders with the insights they need to align asset performance with business objectives.

Within this broad framework, specialized tools are needed to manage the day-to-day activities that keep assets running optimally. Effective maintenance management software helps teams schedule preventive work, manage work orders, control spare parts inventory, and track labor costs efficiently. This technology empowers technicians on the ground to execute the high-level strategy defined by leadership, closing the loop between planning and action.

For a CEO looking to champion this transformation, the path forward involves several key steps:

Conduct a comprehensive audit of all physical assets to establish a clear baseline.

Define clear, measurable key performance indicators (KPIs) for asset performance, uptime, and cost.

Secure executive buy-in and champion the initiative from the top to ensure cross-departmental collaboration.

Select scalable technology partners that align with long-term business goals and can grow with the company.

Foster a culture of continuous improvement by regularly analyzing performance data and refining the strategy.

Ultimately, enterprise asset management is not merely an IT project or a maintenance function; it is a core business strategy. By treating physical assets with the same strategic importance as financial or human capital, leaders can unlock new levels of efficiency, resilience, and profitability. It is time to look beyond the balance sheet and recognize the immense competitive power held within your organization's physical infrastructure.

Follow us on Google News